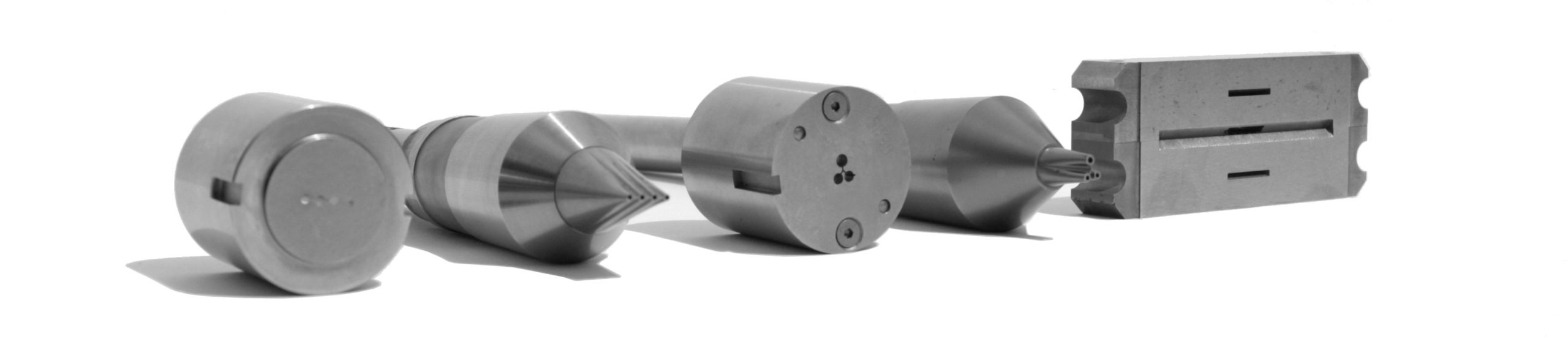

Crossheads for Fluoro Polymer Extrusion

UNITEK fluoro-polymer crossheads have to withstand the hardest conditions.

The microatmosphere which is formed during the extrusion process is strongly corrosive. Therefore all of our crossheads are made out of UNALLOY™, our specially developed fluoro-resistant nickel-based alloy.

Application

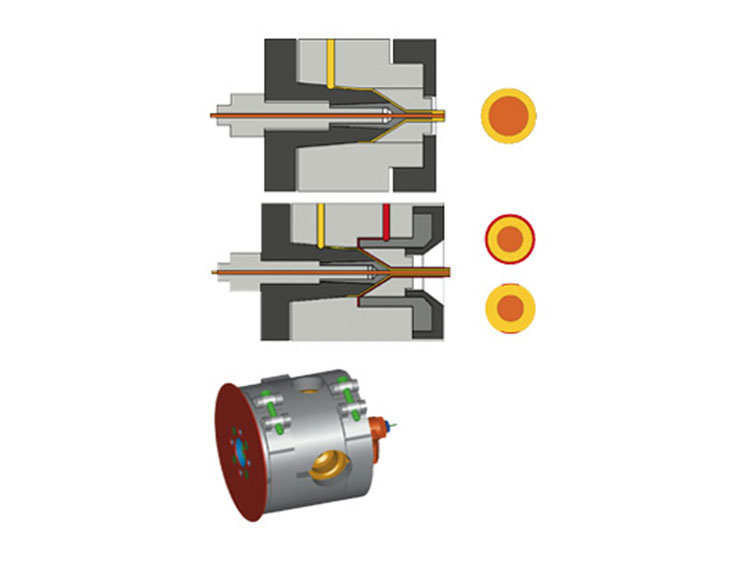

Single Layer extrusion

Co-extrusion for skins and stripe

Centering

Fixed centered crossheads

Fine centered crossheads

Head sizing

From size 1/7 – conductor diameter max. 1mm (0.039″) up to size 40/100 – conductor diameter max. 40mm (1.575″)

Our fluoro-polymer crossheads have to withstand the hardest conditions. The microatmosphere which is formed during the extrusion process is strongly corrosive. Therefore all of our crossheads are made out of UNALLOY™ our specially developed fluoro-resistant nickel-based alloy. In a dedicated multi-step hardening & curing process, we get a low wear material that can be used for many years. Fluoro-polymers are normally processed with tube type toolings. in order to realise big draw down rates, the size of the dies are always one size bigger than the wire guide (tip) sizes. The overall design is very compact with only a few parts to disassemble. The distribution cartridges are designed according to the free flow principle without holes, slots or any blind spots. All fluoro-polymer crossheads will be delivered with high-power heaterbands for temperatures up to 400°C (750F), a vacuum connector, a basic set of tools for the dismantling and maintenance jobs. We can furthermore offer a wide range of options such as adapters, breaker-plates & support solutions. These crossheads can be customized accordind to your needs with all kinds of program inserts for 1, 2 or more stripes as well as specially designed distribution cartridges that exactly suits your product. For more in depth information, please contact our sales team.