Spezialanwendungen

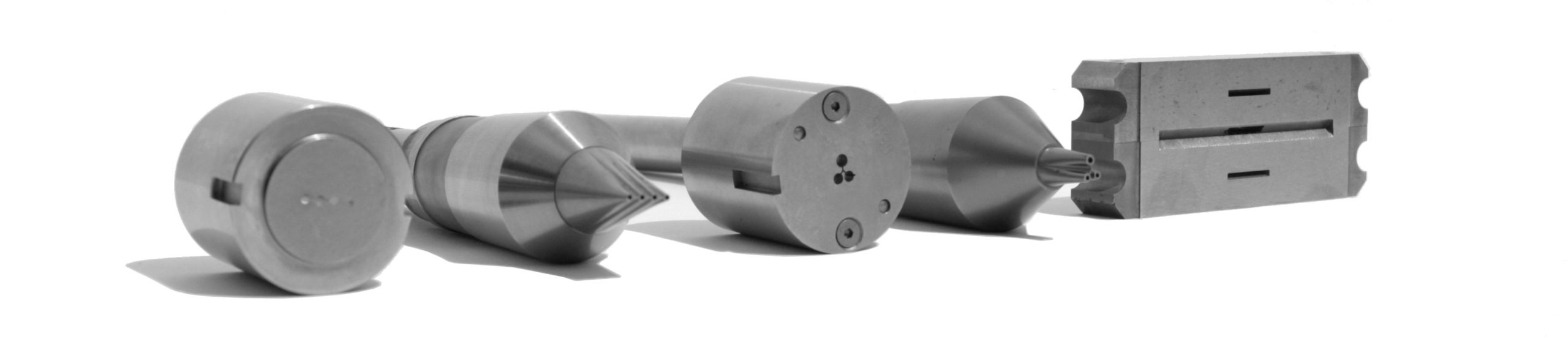

Beispiele für diese Sonderanwendungen sind z.B. Köpfe für die Mikroextrusion von medizinischen Anwendungen, Flachbandköpfe oder Querspritzköpfe mit Zwischenwerkzeugen für Zwickelfüllungen. Desweiteren gehört hierzu auch kundenspezifisches Zubehör wie Adaptoren, Bypässe oder Unterstützungslösungen. Köpfe, die speziell für vorhandene Kundendüsen und -drahtführungen entwickelt werden.

Applikation

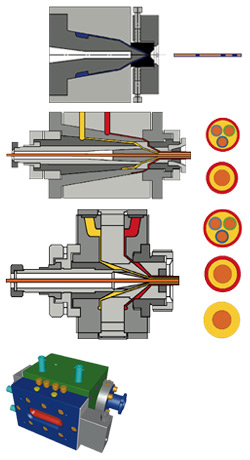

Einschichtextrusion

Co-Extrusion

Mehrschichtextrusion

verschiedene Zentriermöglichkeiten

Festzentrierung

Manuelle Zentrierung

Feinzentrierung

Größen

von Größe 4 - Produktdurchmesser max. 4mm bis Größe 200 - Produktdurchmesser max. 200mm

Flachbandköpfe bis 180mm Breite

Sie haben haben noch eine große Anzahl an Düsen und Drahtführungen mit Nicht-Standardaufnahmen? Kein Problem, wir können unsere Verteiler so adaptieren, daß Sie Ihre vorhandenen Werkzeuge verwenden können. Unsere Sonderprogramm umfasst alle Anwendungen, die nicht durch unsere Serienteile abgedeckt werden können. Dies sind z.B. Köpfe für die Mikroextrusion von medizinischen Anwendungen, Flachbandköpfe für Aufzugskabel oder Verpackungsbänder. Desweiteren Querspritzköpfe mit Temperaturtrennung für die Verarbeitung von Polymeren mit unterschiedlichen Schmelzpunkten oder Köpfe mit Zwischenwerkzeugen für Zwickelfüllungen. Wir fertigen auch gerne Ihr kundenspezifisches Zubehör wie Adaptoren, Bypässe oder Unterstützungslösungen.

Ein- oder Mehrschichtextrusion

For low-output and low-viscosity material

SL = for single layer extrusion

SK = for additional co-extrusion of skin

ST = for additional co-extrusion of stripe

Kopfgrößen bis Ø100 Kabeldurchmesser

These heads use an additional extrusion tool between standard type wire guide and die for a separated extrusion of two identical or two different materials in one head such as bedding plus heating compound.

DL = for dual layer extrusion

SC = fixed centered

MC = manually centered

S = for additional extrusion of stripe

DLV = for additional extrusion of skin

SZ crossheads

Extremely compact heads for SZ-stranding-tandem extrusion of flexible cores.

SL = for single layer extrusion

DL = for dual layer extrusion

DL crossheads

These heads are designed for the co-extrusion of polymers with similar melt temperatures

Crossheads with thermal barrier

These heads are available for co-extrusion with melt temperature differences of up to 100°C (212°F).

Liquid medium temperature controlled crossheads

Crossheads for rubber of cross-linked material extrusion.